Gauge & Fixture Design

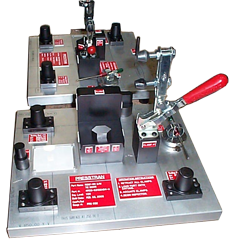

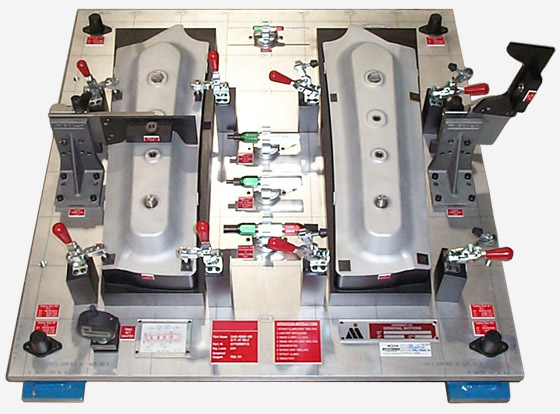

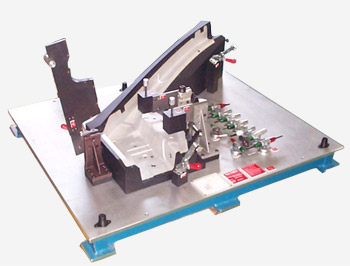

ComPuTool Gauge & Fixture produces gauge and fixture designs for production environments. Our gauge design concepts factor in ergonomics, usability, checking method preferences, durability, and fixture maintenance.

We can produce gauge designs from customer supplied 2D drawings, STEP or IGES files, or part prototypes. Our in-house gauge designers produce solid-model concepts for customer review prior to manufacturing.

Our gauges and fixture will accurately check your production parts. We can check for flatness, profile, and perpendicularity. Our gauges can inspect for burrs, punch breaks, material defects, material flash, etc. depending on the part material. We anticipate tool wear during your part production and make allowances in the gauge.

Gauge & Fixture Ergonomics

Our gauge and fixture designs pay close attention to operator ergonomics and safety. Our gauges and fixtures are designed for ease of part load and unload. Height-adjustable carts or table-mounted gauges reduce the reliance on operator strength, size, or height. Operator safety concerns, which can reduce inspection efficiency, are addressed by minimizing pinch points, burrs, and sharp edges on all exposed surfaces.

We design all gauges and fixtures for intuitive use through thoughtful placement of clamps and inspection tools. We make use of colour-coding and shape-coding. As a result, minimal operator training is required for gauge use. Part placement, part clamping, and part inspection follow a natural operator movement. Our attention to intuitive design enhances gauge usability and achieves faster part checking.